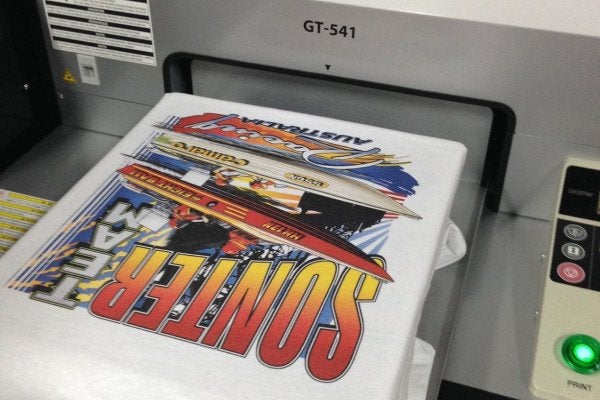

Direct to garment printing (DTG printing), like the name suggests, is a printing method where an image is directly printed onto preferably cotton garments with digital inkjet technology, using special water-based ink. The results are bright full-colour designs.

Unlike screen printing, DTG is perfect for short runs, vibrant photographic or full colour prints onto a wide range of apparel. Set up is far less labour intensive, therefore is a faster, cleaner and economical process. Where screen printing applies ink onto the top of the material, DTG injects colour pigments into the fabric fibres, creating a softer feel. Prints don't crack or peel and the garment can be stretched without affecting the design. DTG can also seamlessly print over zippers and other difficult areas on garments.

This method does come with some limitations. The preferred fabric to print on is 100% combed cotton (or other natural fabrics). Colours cannot be matched exactly with the Pantone matching system. The appearance of colours in the final product may be affected by the colour of the fabric. Set up costs are generally low, but sometimes images can become pixelated after printing. Some aftercare is also required.

Our Fully Promoted consultants will work with you on how best to brand your team or business.

The first thing is ensuring the choice of garment is suited for DTG. The garment is then cured with a heat press. The heat removes any moisture to ensure a flat printing surface. If printing with white inks, the garment must also be pre-treated before curing.

We then prepare the artwork you provide before sending it to print. The garment is placed on a plate and printed on. Afterwards, the ink on the garment must be cured again to dry and permanently affix the ink to the garment, ensuring its durability and washability.

DTG is still the method of choice for small to medium print jobs that require fast turnaround with detailed artwork and unlimited colour options. It is cheaper to do repeat print runs, and is flexible for a range of clothing, with minimal set up.

Yes! One major advantage is being able to print with white ink.